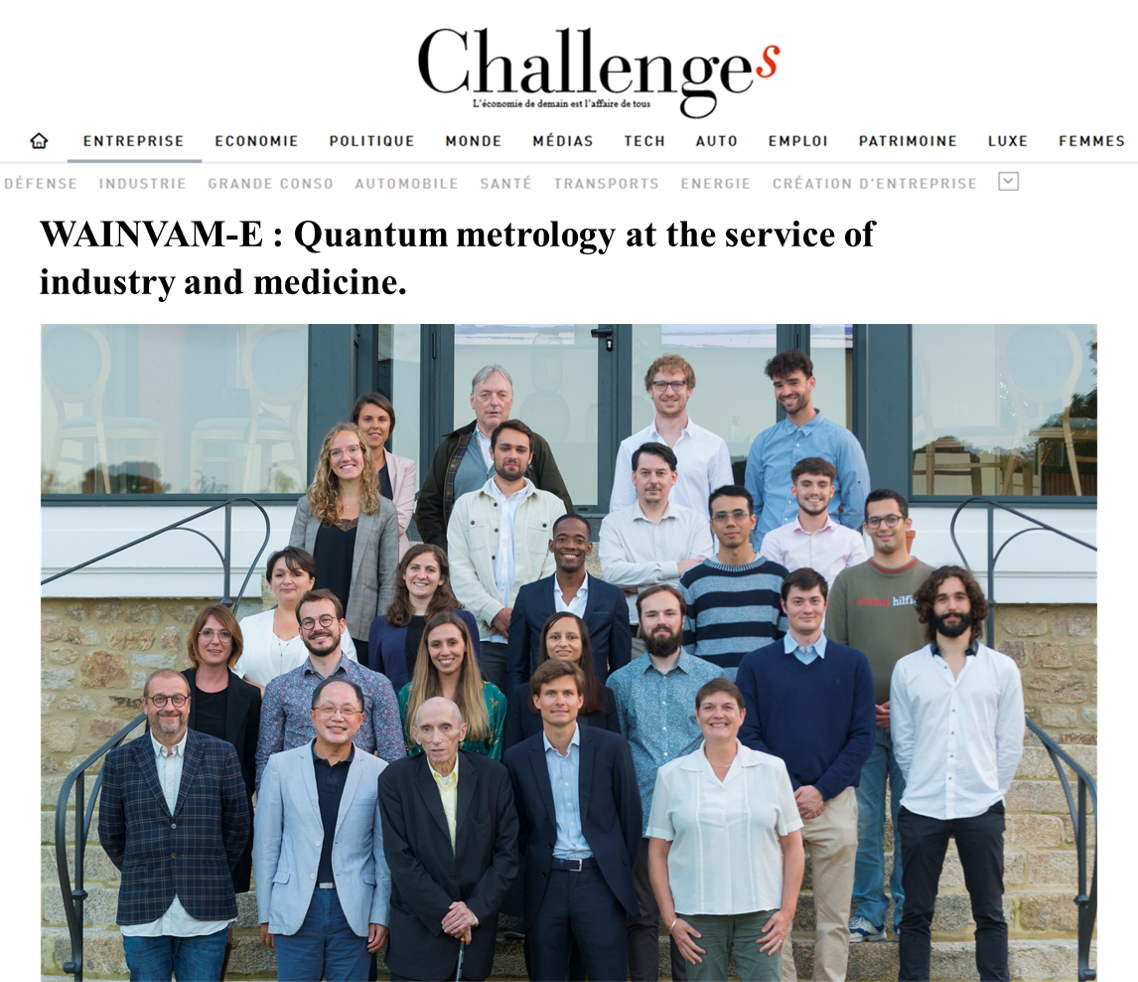

Innovative start-up, WAINVAM-E develops ultra-sensitive quantum sensors, very resistant, capable of measuring infinitesimal variations of magnetic fields, with innovative applications for the industrial and health fields. We met Remi Geiger and Michel Féret, co-founders of the company.

What is the genesis of WAINVAM-E?

Michel Féret : In June 2019, Claude Barraud, with a long career in industry, met Remi Geiger, an expert in metrology and quantum sensors. They decide to create a company that decompartmentalizes research, guided by the conviction that scientific interdisciplinarity is the key to inventing the technologies of the future.

Remi Geiger : Michel Féret, PhD in AI, and Jianguo Zhang, PhD in electrochemistry, have joined us. WAINVAM-E was born in the spring of 2020 and we now have twenty-six people. Being a commercial company and not only a research center, we meet many industrial and healthcare players to answer their use cases and concrete needs with our technologies, products and services. In 2021, we were awarded the I-LAB innovation competition, and received a Deeptech innovation grant from the BPI. We plan to raise funds in spring 2022.

What is the challenge of metrology?

Metrology is the science of quantifying measurement uncertainties, which is necessary for good decision-making. For example, accessories as distinct as a GPS or a bathroom scale are metrological tools. We have found that adapting this science to the medical field allows us to detect a disease more quickly and implement the appropriate treatment. This same principle applies to industrial control: when you pump hydrocarbons or water into the ground, for example, knowing the exact level of corrosion in the pipe can prevent considerable risks. Similarly, it is essential to detect material loss, wear, cracks, or structural fatigue in pipes, tanks or structures used in the nuclear or oil industry. This metrology allows prevention in the sanitary, environmental and industrial fields, resulting in significant savings for companies.

Does your technology address these issues?

Our sensors are based on the optical and quantum properties of diamonds with NV (Nitrogen – Vacancy) centers that push the current limits of perception. This process is the result of 25 years of fundamental research conducted around the world, but remains unknown to industry. However, for industrialists, our technology has a very vast potential since our sensors can detect corrosion, estimate the thickness of a wall or the wear of a material. Our magnetic field sensors are made of diamonds and are incomparably robust and stable. The many possible applications have a very high economic, ecological and human impact since they avoid energy losses and the risks of industrial accidents with strong ecological impacts.

In a similar way, in the medical field, we can give a function to our nanodiamonds so that they reach a specific biological target, and if necessary deliver an active principle. In the case of cardiovascular, infectious, neurodegenerative or cancer diseases, the body carries a certain number of markers, and our detection methods make it possible to identify these disorders at an early stage from a simple drop of blood. To do this, we use a combination of quantum physics, chemistry, biology and clinical skills – a true interdisciplinarity that is a major obstacle in hospitals today. Our methodology is applicable to many diseases, from Alzheimer’s to lung cancer.